Brief About the Project

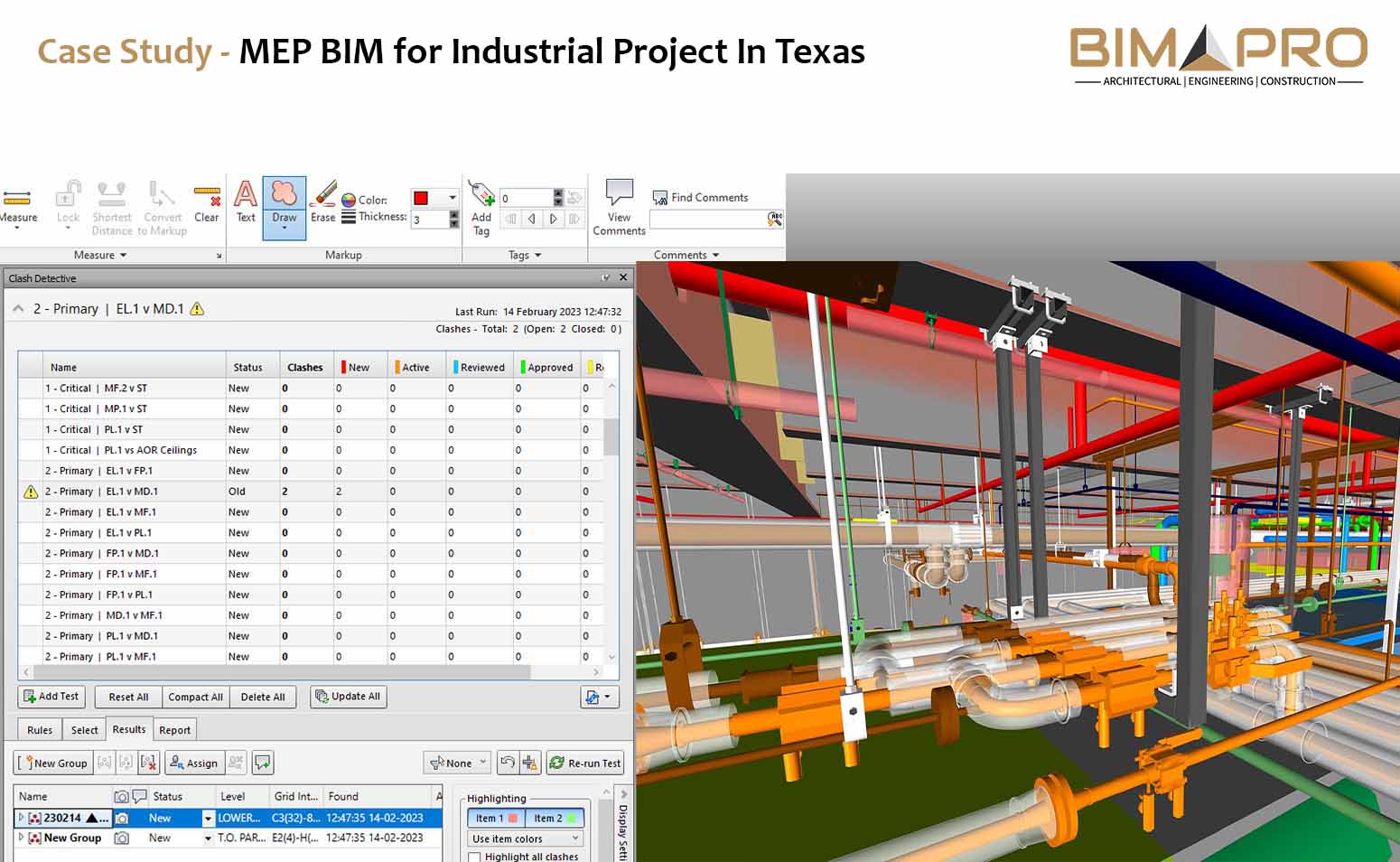

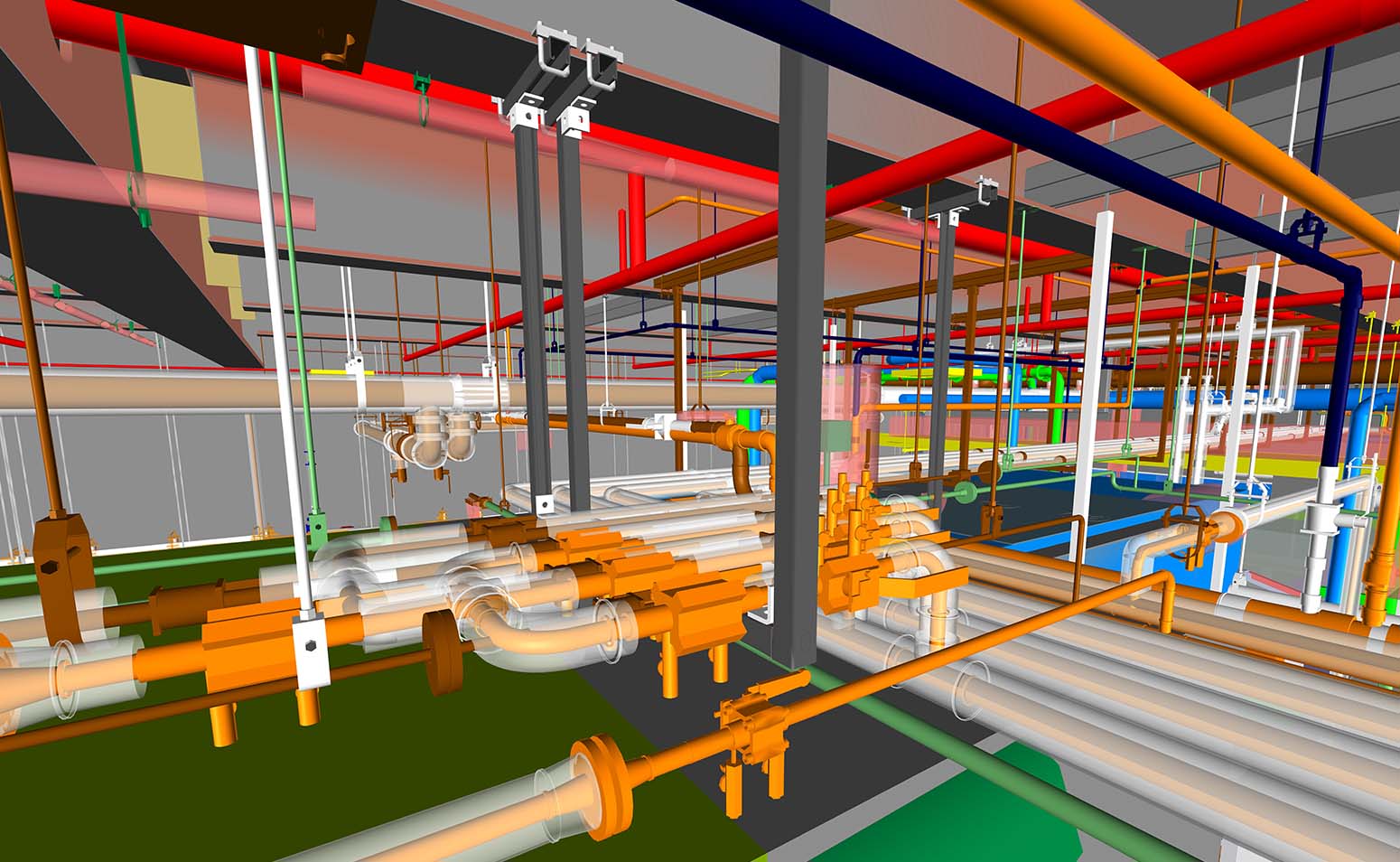

In the heart of Texas, a large industrial manufacturing firm sought to optimize its operations and streamline project management for an existing facility. As a BIM Services provider based in Texas, BIMPRO was entrusted with the task of delivering MEP BIM Services for industrial manufacturing project including MEP (Mechanical, Electrical, and Plumbing) modeling, clash coordination, and shop drawings detailing, spool drawings services to support this ambitious project. This case study explores our journey working with the contractors of this manufacturing project, highlighting the challenges, solutions, collaboration, and ultimately the successful project delivery.

Our client, a prominent contractor firm in Texas, specializes in the installation and construction of the industrial MEP systems. They had embarked BIMPRO on the renovation of existing project that required precise MEP modeling and BIM coordination from the Construction Documents set to facilitate smooth field coordination, installation and construction process.

Project Details

Client: MEP Contractor

Project Location: Austin, Texas

Project Area: Approx. 425,500 sq.ft

Building Type: Industrial and Manufacturing

Software: Authoring tool Revit, Coordination tool Navsiworks, and AutoCAD

Services Provide: MEP BIM Services | Clash Detection Services | Shop Drawings Services | BIM Coordination Services

Project Scope

Their primary objective was to create a detailed MEP model for a Texas manufacturing firm. The project scope included:

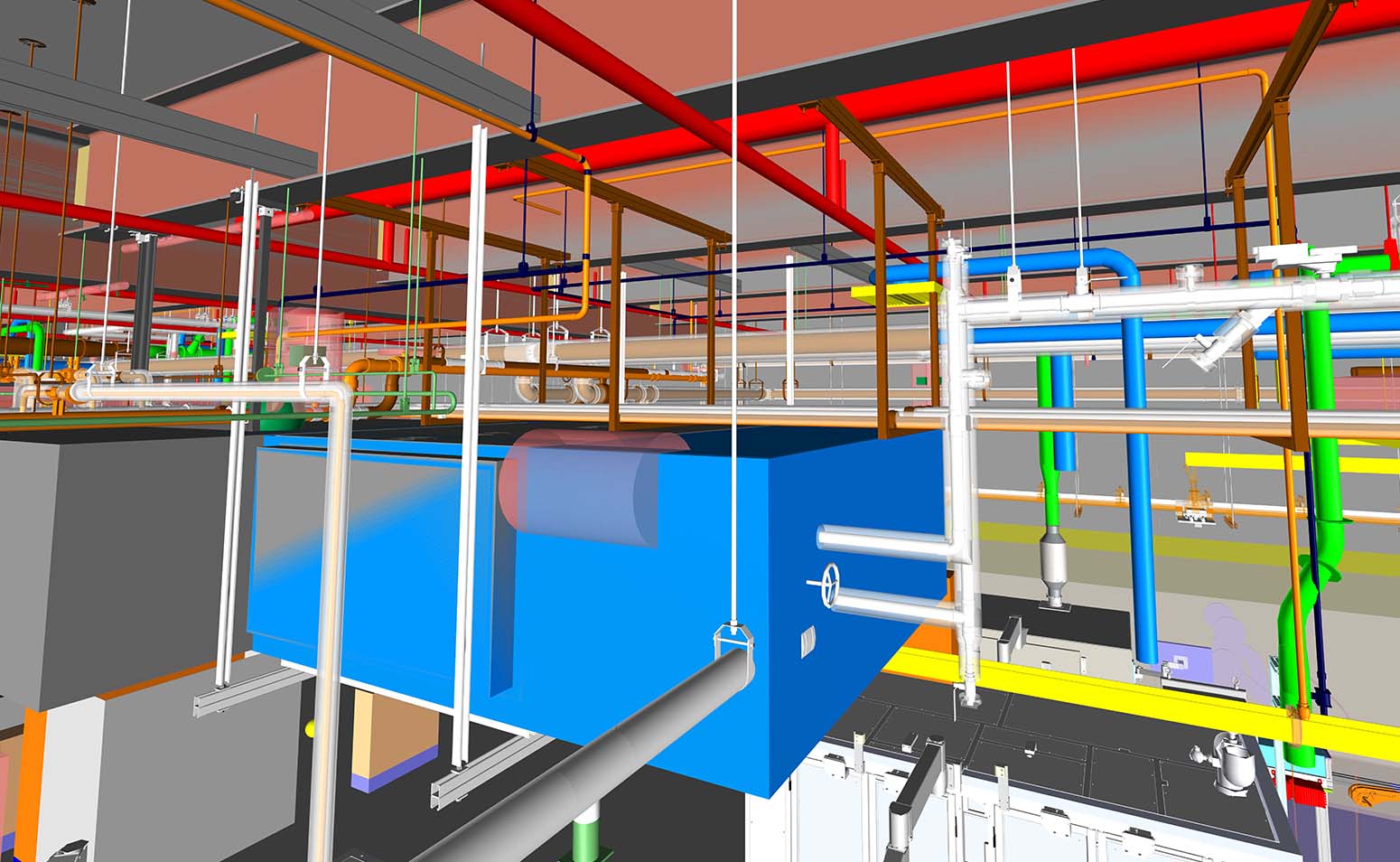

- MEP Modeling: Develop a comprehensive 3D MEP model that accurately represents the mechanical, electrical, and plumbing systems of the facility.

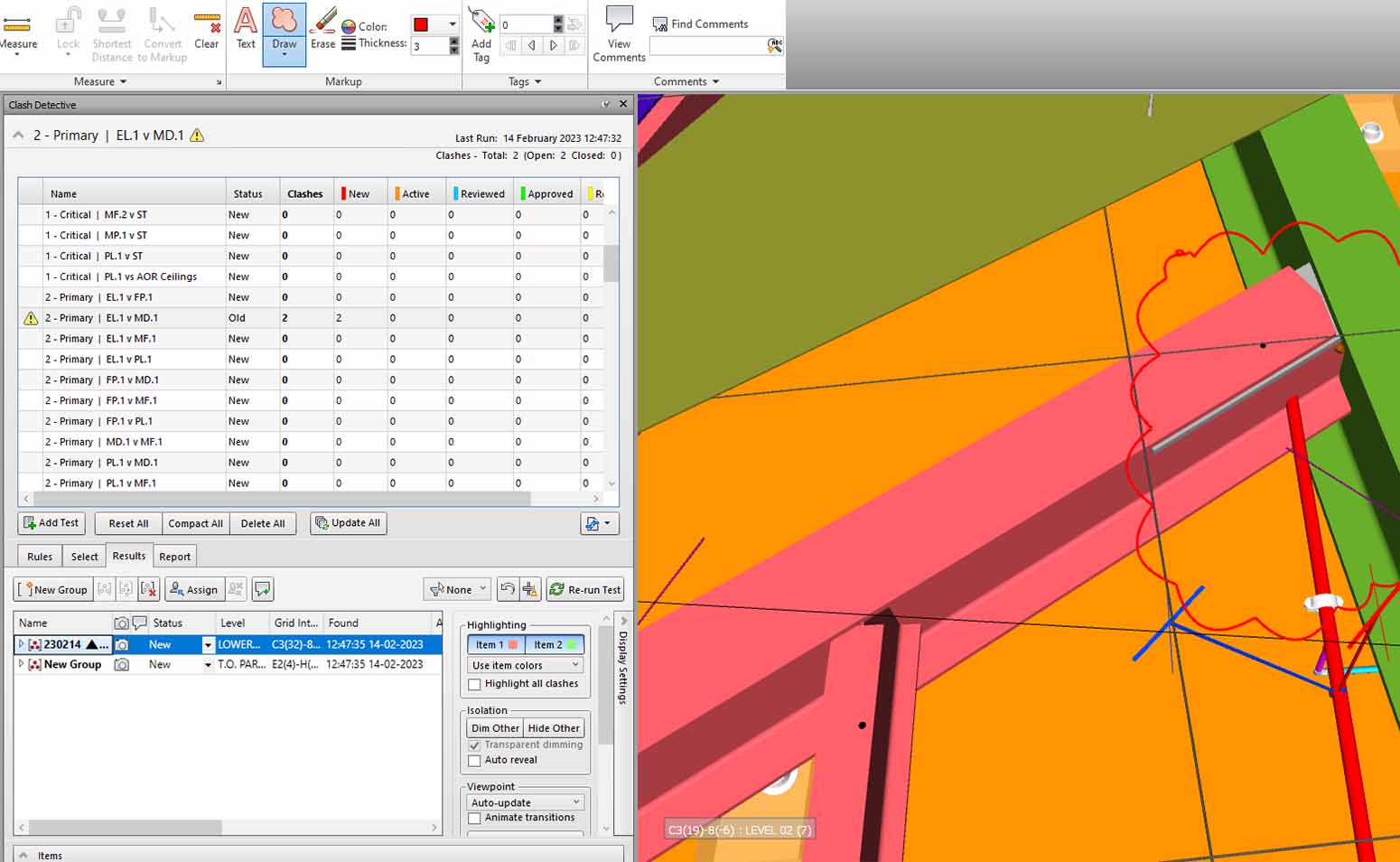

- Clash Coordination: Identify and rectify clashes among various MEP components to ensure smooth operations and minimal errors during construction.

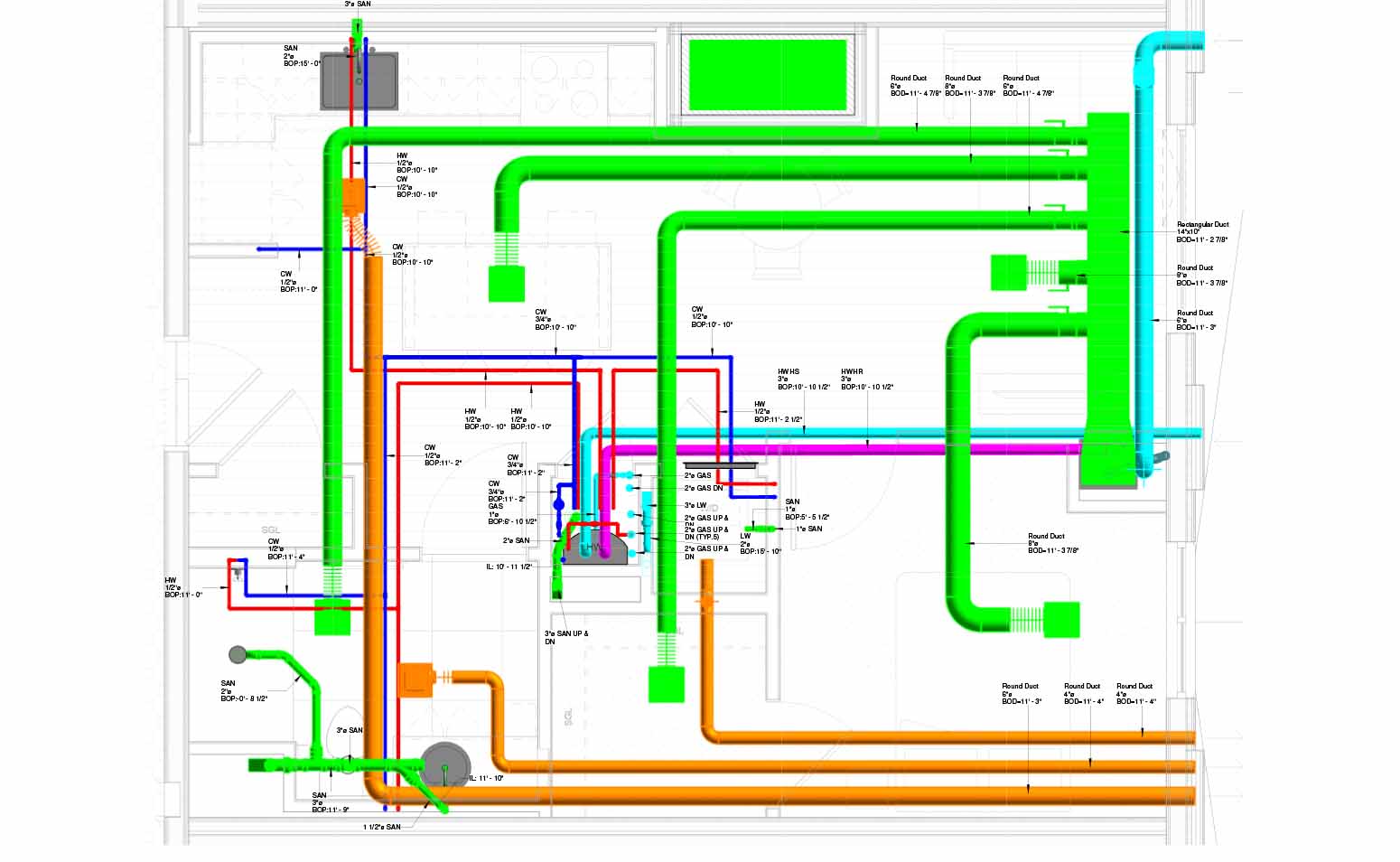

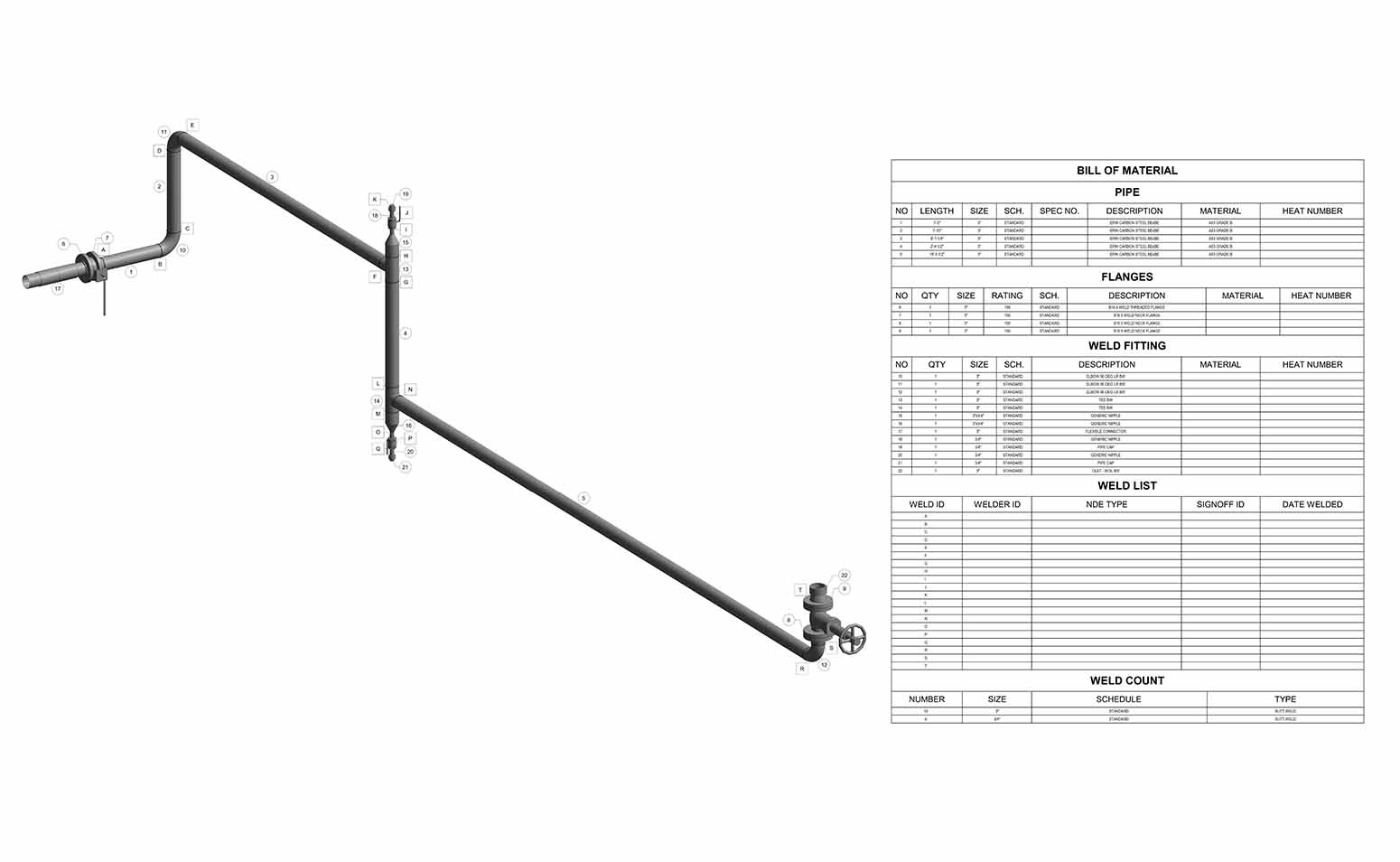

- Shop Drawings: Create detailed shop drawings LOD 400 that provide precise manufacturing instructions for MEP components, ensuring consistency and quality in the products manufactured.

- Spool Drawings Detailing: Generate spool drawings that outline the exact measurements and specifications for pipes, ducts and more, facilitating their efficient installation in the field.

Challenges Faced

Several significant challenges presented themselves during the course of the project:

- Complex MEP System: The industrial project featured an intricate MEP system with numerous components and systems that needed precise modeling and coordination.

- Clash Coordination: Ensuring that MEP components didn’t interfere with each other and operated seamlessly was a top priority to prevent costly field errors.

- Minimum Field Errors: The client demanded a minimal margin of error during the manufacturing and installation phases to avoid costly rework and delays.

- Tight Deadlines: The project timeline was extremely tight, adding pressure to deliver accurate results promptly.

Our Strategic and Specific Approach

BIMPRO addressed these challenges with a comprehensive and systematic approach:

- Dedicated Team and Resources: We assembled a flexible and dedicated team of skilled BIM professionals with extensive experience in industrial projects. Adequate resources were allocated to meet the project’s demands.

- Streamlined Process: We implemented a streamlined BIM process that incorporated the latest technologies and software tools like Revit, Navisworks for efficient modeling, coordination, and drawing creation.

- Effective Communication: Clear and regular communication channels were established with the client to ensure that project objectives and milestones were understood and met.

- Accurate Modeling and Coordination: Our team meticulously created a precise MEP model, focusing on coordination from the outset to minimize clashes. This approach allowed us to detect and rectify issues early in the manufacturing, installation and construction phase.

- Accurate Shop Drawings and Spool Drawings: We produced highly detailed shop and spool drawings, aligning them with the MEP model to guarantee the accuracy of components to be manufactured and installed.

- Modeling and Coordination Simultaneously: To minimize clashes further, we synchronized the modeling and coordination processes, allowing for immediate adjustments whenever a clash was detected. Attended virtual meetings whenever required to resolve the clashes.

Client Testimonial - Let's hear what they say about BIMPRO!

“Working with the BIMPRO, LLC a BIM Services team in Texas was a game-changer for our project. Their dedication, expertise, precision, and efficient workflow allowed us to meet our tight deadlines and ensure a seamless integration of our manufacturing facility’s MEP systems. Their commitment to clear communication and professionalism throughout the project was instrumental in the project’s success.” We will reach out to BIMPRO for our BIM required projects in future and would recommend them to others who might need BIM services provider like BIMPRO for their projects.

– Project Manager

Conclusion

Despite the complexities and tight deadlines, our collaborative efforts resulted in an efficient project that met the client’s expectations and minimized field errors. This case study exemplifies BIMPRO’s capability to provide innovative BIM solutions that enhance efficiency and quality in industrial manufacturing projects.

Our commitment to delivering peace, value, and quality through our expertise in Revit modeling services reaffirms our position as a trusted partner for industries seeking to optimize their projects.

If you’re seeking BIM solutions that can bring your projects to life, contact us today, and let us help you achieve your goals, just as we did for this contracting firm for this manufacturing project in Texas.