Structural BIM and Shop Drawings Services in Texas

Structural BIM Services for Structural Contractor in San Antonio, TX

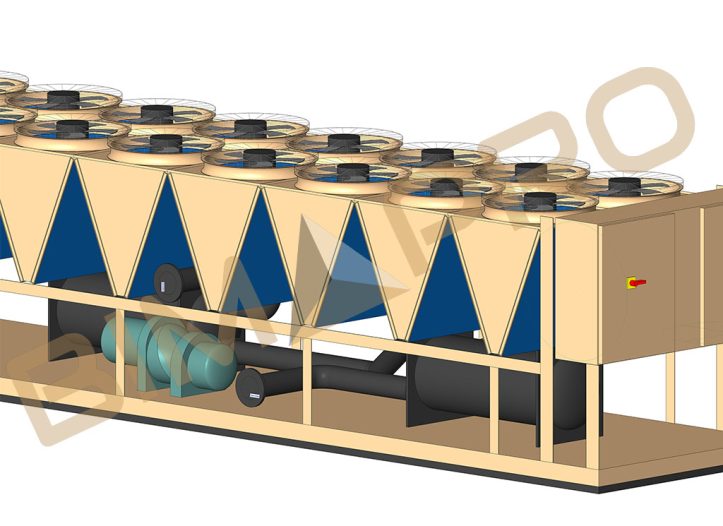

BIMPRO LLC collaborated with structural contractors in San Antonio, Texas to deliver precise and detailed Structural BIM Modeling and Shop Drawing Services. Our team developed accurate 3D models and high-quality erection drawings tailored to the unique project requirements, manufacturing, installation, smooth construction workflow.

Client: Structural Contractor in San Antonio, Texas

Services Provided: Structural Modeling Services, Shop Drawings Services

Software: Tekla

500+

Successful Projects

5+

Years of Experience

10+

Sectors Served

Scope of Work

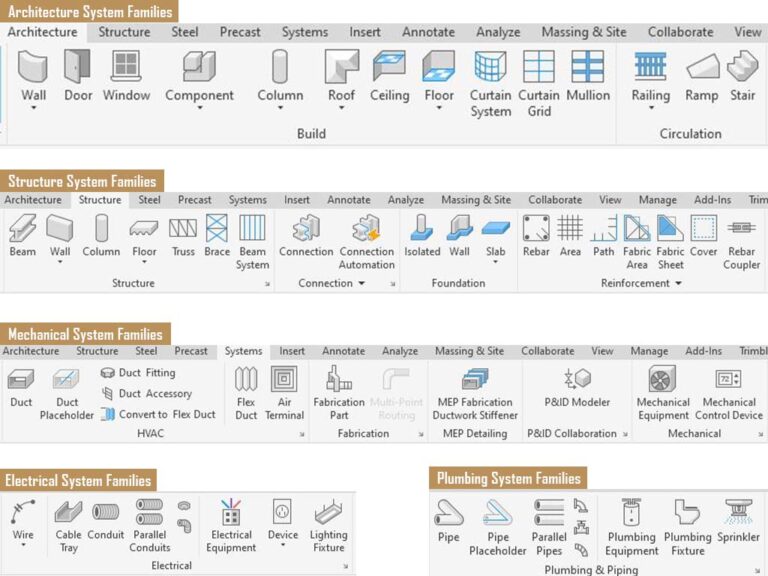

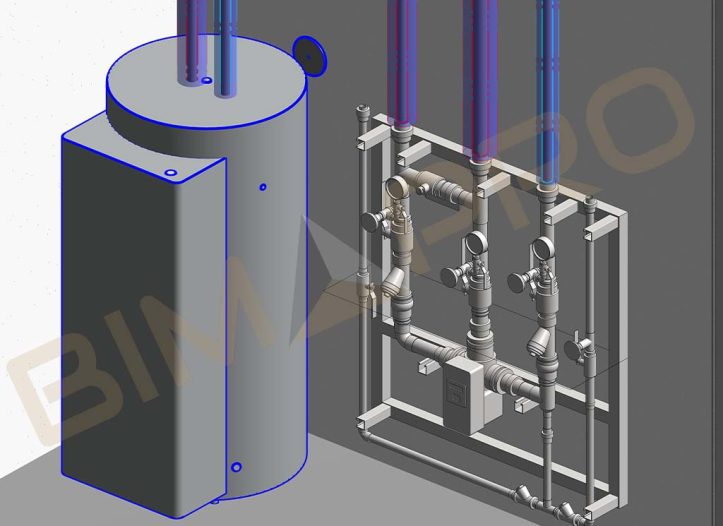

1. Structural BIM Modeling

We created intelligent 3D models that encompassed all structural elements, including:

- Columns, beams, slabs, and foundations.

- Steel connections and reinforcements.

- Clash detection and resolution to ensure constructability.

We adhered to industry standards such as ACI, AISC, and Texas-specific building codes, ensuring compliance and precision.

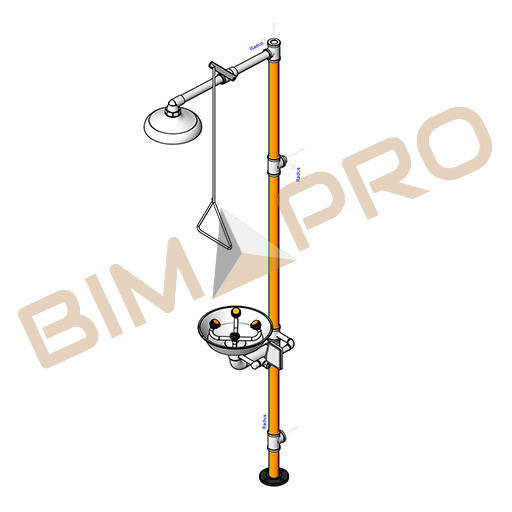

2. Shop Drawings

We provided shop drawings that featured:

- Detailed section views, elevations, and dimensions.

- Connection details for steel and concrete components.

- Fabrication-ready detailing to enhance material accuracy and reduce wastage.

These shop drawings were instrumental in coordinating between design and construction teams, ensuring error-free installations.

3. Bill of Materials (BOM)

Our team delivered an exhaustive Bill of Materials that included:

- Quantities of structural elements like steel, rebar, and concrete.

- Specifications for procurement, including material grades and dimensions.

- Cost estimates to facilitate budgeting and material planning.

This ensured contractors had a clear roadmap for resource allocation and minimized project delays.

Why Choose BIMPRO?

BIMPRO LLC stands out as a reliable partner for architects, engineers, contractors for small to large scale projects in USA, offering comprehensive BIM services in USA that bridge the gap between design and construction. With a commitment to quality and precision, we empower our clients to achieve construction success with efficiency and accuracy.

Let us take your structural projects to the next level with our advanced BIM expertise.

Explore More BIM Projects

Structural BIM Services for Structural Contractor in San Antonio, TX BIMPRO LLC collaborated with structural contractors in San Antonio, Texas to deliver …

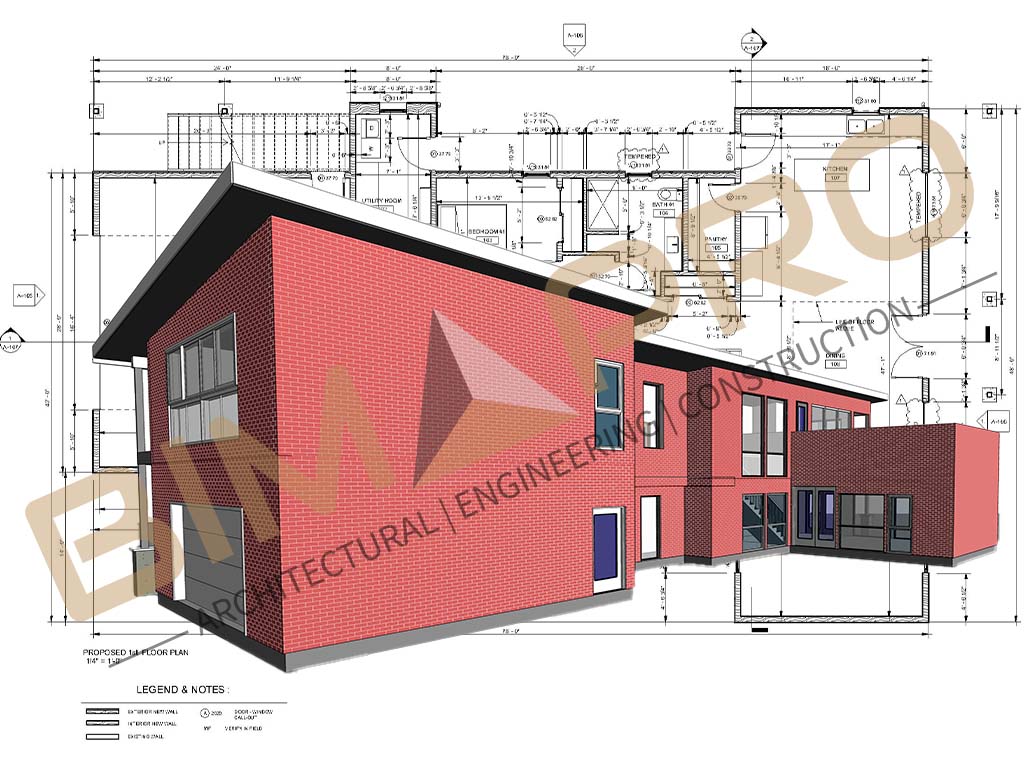

BIM Modeling and Coordination Services for Educational Project in Austin, TX BIMPRO LLC delivered top-notch Architectural and MEP BIM services for High …

Clash Coordination Services for Residential Project in Houston, TX BIMPRO has provided MEP clash coordination services for a high-rise apartment project in …

Scan to BIM Services for Wharehouse Project in Jacksonville, FL We have provided Scan to BIM services for a warehouse project located …